Building a Better Scaffold for 3D Bioprinting

Posted on by Dr. Francis Collins

When the heart or another part of the body fails, a transplant is sometimes the only option. Still, the demand for donated organs far outpaces supply, with thousands of people on waiting lists. Furthermore, transplants currently require long term immunosuppression to prevent rejection. Wouldn’t it be even better to create the needed body part from the individual’s own cells? While it may sound too good to be true, research is moving us closer to the day when it may be possible to use 3D printing technology to meet some of this demand, as well as address a variety of other biomedical challenges.

In a study published in the journal Science Advances [1], an NIH-funded team from Carnegie Mellon University, Pittsburgh, recently modified an off-the-shelf 3D printer to create gel-like scaffolds that could be seeded with living cells to produce coronary arteries, an embryonic heart, and a variety of other tissues and organs.These researchers, of course, aren’t the only ones making progress in the rapidly emerging field of bioprinting. Using more costly, highly specialized 3D printing systems, other groups have crafted customized joints, bones, and splints out of hard, synthetic materials [2], as well as produced tissues and miniature organs by printing and layering sheets of human cells [3]. What distinguishes the new approach is its more affordable printer; its open-source software; and, perhaps most importantly, its ability to print soft, biological scaffolds that set the stage for the creation of custom-made tissues and organs with unprecedented anatomical detail.

Soft biomaterials are notoriously difficult for tissue engineers to work with in three dimensions. Scaffolds printed out of such materials have a way of collapsing under their own weight, and that has limited the production of larger and more complex bioprinted structures that recapitulate the microarchitecture seen in real tissues. To get around this problem, the Carnegie Mellon team, which was led by NIH New Innovator Award winner Adam Feinberg and graduate student Thomas Hinton, used a gel-in-a-gel technique dubbed Freeform Reversible Embedding of Suspended Hydrogels (FRESH).

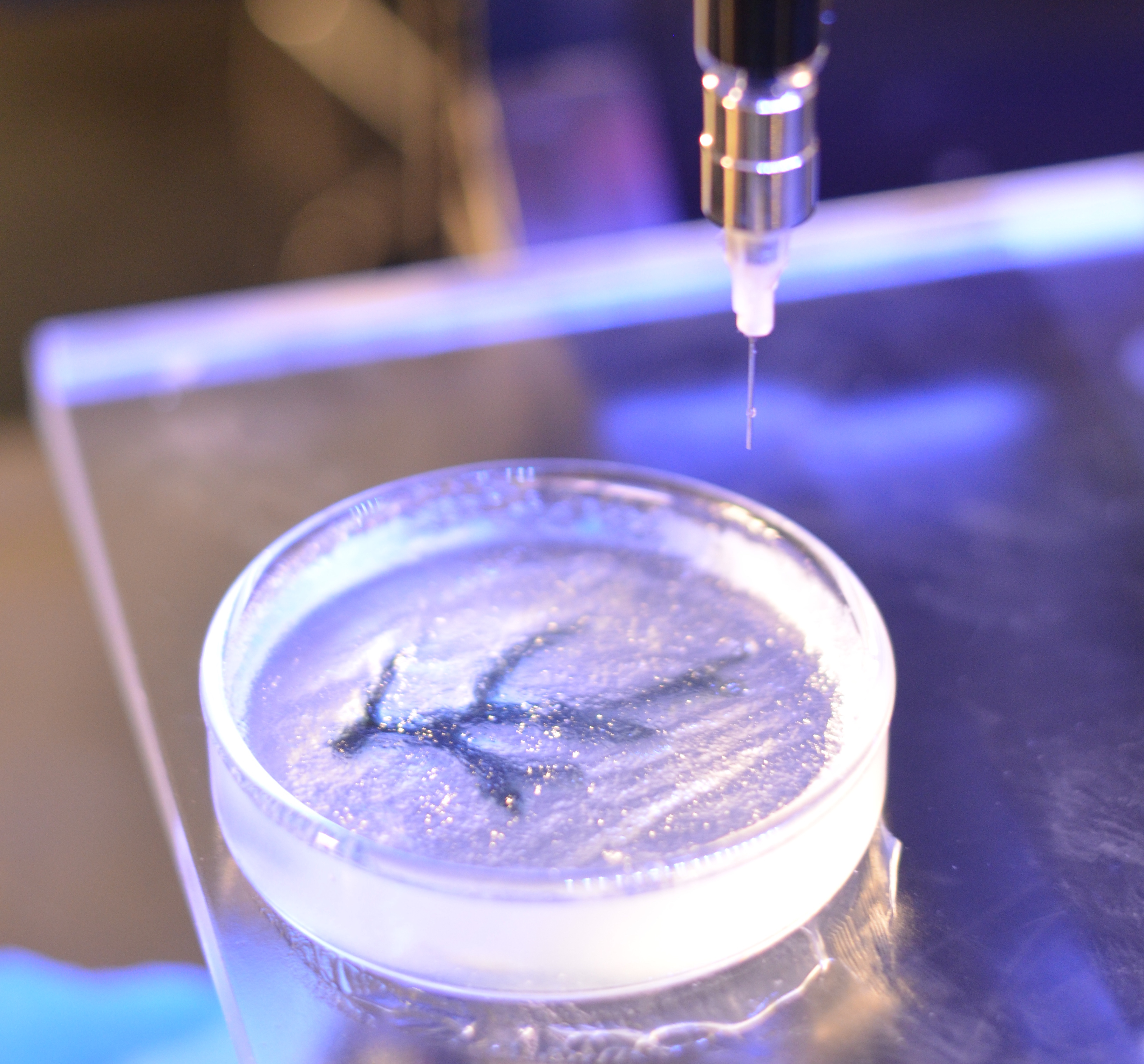

The new approach involves printing soft biomaterials—in this case, the proteins collagen and fibrin and the polysaccharide alginate—inside a thick slurry of gelatin microparticles and water in a Petri dish. The slurry easily flows around the needle of the 3D printer as it moves, while the soft biomaterials being extruded are embedded, as if in a solid support, during the layer-by-layer printing process. Once the scaffolds are fully printed, the gelatin is removed by warming the lab dish to 37°C, revealing the finished replica of an organ or tissue. Cells can be added either during or after the printing process is complete, and Feinberg’s team has successfully performed FRESH bioprinting using live cells.

The researchers demonstrated the utility of their technique by producing a variety of scaffolds based on 3D images of organs and tissues—structures that, while anatomically correct, were not functional. These structures included: a to-scale model of a human coronary artery; an oversized replica of an embryonic chick heart, including its internal chambers; and a miniaturized model of the surface of the human brain. The production process took anywhere from 20 minutes to 2 hours and required only readily available, relatively low-cost materials. For more details, check out this 7-second, time-lapse video showing production of a coronary artery.

The team’s next step will be to add stem cell-derived human heart cells to the scaffolds in an effort to produce dynamic, living heart muscle that could be used for testing the safety of potential new drugs. Further down the road, if the cells used for the bioprinting are derived from the person in need of a transplant, through powerful new methods that can make induced pluripotent stem cells (iPSCs) from skin or blood samples, this approach might lead to heart repair and organ transplants that require no immune suppression.

In the meantime, this latest demonstration shows just how accessible bioprinting has become to researchers interested in putting it to work for almost any biomedical application they can dream up. Like many other groups, the Feinberg lab is generously sharing its knowledge with the worldwide scientific community via the NIH 3D Print Exchange, which offers a unique set of tools to create and share 3D-printable models related to biomedical science.

References:

[1] Three-dimensional printing of complex biological structures by freeform reversible embedding of suspended hydrogels. Hinton TJ, Jallerat Q, Palchesko RN, Park JH, Grodzicki H-J S, Ramadan MH, Hudson AR, Feinberg AW. Science Advances. 23 Oct 2015. [Epub ahead of print]

[2] The printed organs coming to a body near you. Ledford H. Nature. 2015 Apr 16;520(7547):273.

[3] 3D bioprinting of tissues and organs. Murphy SV, Atala A. Nat Biotechnol. 2014 Aug;32(8):773-85.

Links:

Tissue Engineering and Regenerative Medicine (National Institute of Biomedical Imaging and Bioengineering/NIH)

Regenerative Biomaterials and Therapeutics Group (Carnegie Mellon University, Pittsburgh, PA)

Video: Adam Feinberg on Tissue Engineering to Treat Human Disease

NIH Director’s New Innovator Award (Common Fund)

NIH Support: Common Fund

Share this:

- Click to share on LinkedIn (Opens in new window)

- Click to share on Pinterest (Opens in new window)

- Click to share on Tumblr (Opens in new window)

- Click to share on Reddit (Opens in new window)

- Click to share on Telegram (Opens in new window)

- Click to share on WhatsApp (Opens in new window)

- Click to print (Opens in new window)

Tags: 3D printing, alginate, biomaterials, bioprinting, collagen, coronary artery, fibrin, Freeform Reversible Embedding of Suspended Hydrogels, FRESH bioprinting, gelatin, heart, NIH 3D Print Exchange, NIH New Innovator Award, organ transplant, soft biomaterials, tissue engineering, tissue scaffold

Good article.